Taylor made production cycle

Blacks offers its customers a production cycle tailored to meet the specific needs of each project. Our work team manages every step of the process: from design to the final production of the product, with a constant emphasis on quality and efficiency.

_01

Engineering

Specifications

Up to 20 workstations

Rhinoceros

Catia V5

Solid works + 3d experience premium

Laminate tools by Anaglyph

Blacks' technical office department is at the heart of the design. We develop innovative designs for advanced composite products, ensuring that every project is optimized for specific production needs, from prototyping to small and medium series.

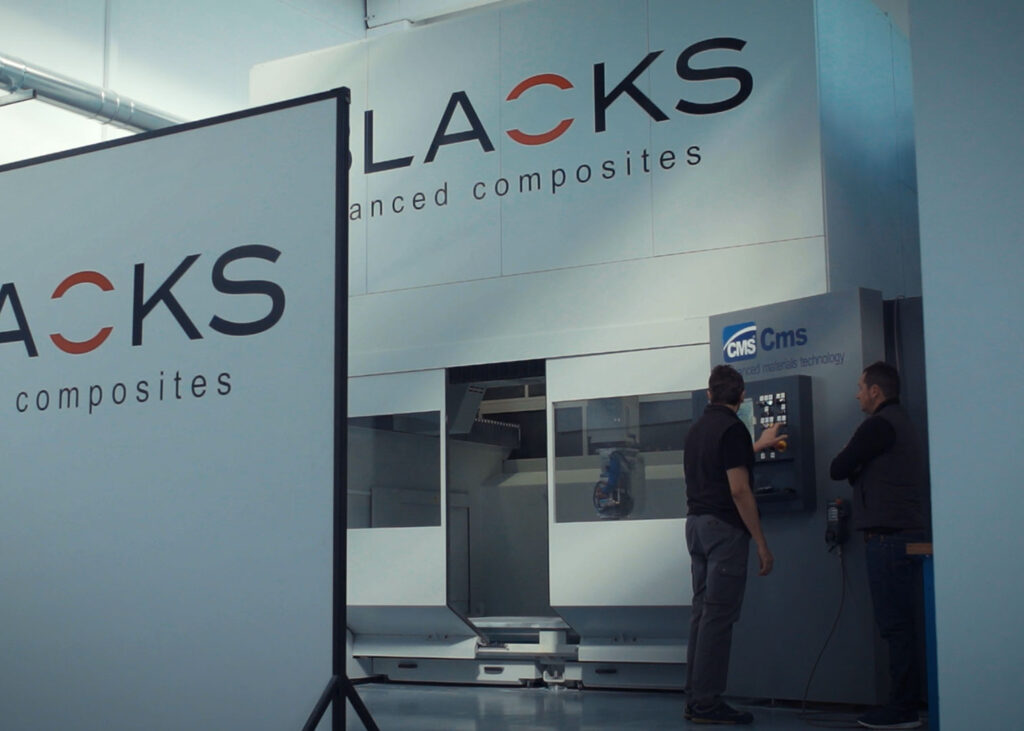

_02

Modelling

Specifications

350 sqm. dedicated area

5-axis Antares CMS 26/15

Travels of 2600 x 1500 x 1200mm

Software: AUTODESKPOWERMILL POWERSHAPE

Stratasys Fortus 450mc

Technology: Fused Deposition Modeling (FDM)

Printing area: 406 x 355 x 406 mm

Formlab Form 3L

Technology: Low Force Stereolithography (LFS)

Printing area: 335 x 205 x 300 mm

Modelling is the department in which projects are transformed into tangible reality: with an artisanal attention to detail and the use of technologically advanced tools, we create precision models that are then used in the subsequent production phases.

_03

Cutting

Specifications

n. 3 Cutting Trading HI RAPTOR

1 – Size 2.60 m x 4.20 m with conveyor bed.

Precision 0.2mm

Maximum speed 1200 mm/s

2 – Size 2.60 m x 4.20 m with conveyor bed.

Precision 0.2mm

Maximum speed 1200 mm/s

3 – Size 2.10m x 3.20m with conveyor bed

Precision 0.2mm

Maximum speed 1200 mm/s

In the cutting department we use precision machinery to process materials with the utmost accuracy. Our advanced equipment and careful artisanal know-how ensure that every cut is made with extreme precision, guaranteeing high efficiency and minimising waste.

_04

Lamination in clean room

Specifications

750 mq. lamination area, ISO 8 clean room with filtered air, controlled humidity and higher air, pressure compared to the outside.

Up to 120 workstations

The clean room is an area dedicated to rolling, where attention to purity and quality of the environment is crucial. Here, in a controlled environment, composite materials are prepared to ensure that they are free of contamination, and therefore perfect for high quality productions.

_05

Autoclave curing

Specifications

n.4 autoclaves:

1 – Autoclave (Magnabosco)

Working size: 1.4 m (Ø) x 6.0 m

T up to 200°C; p up to 7 bar

2 – Autoclave (Irop)

Working size: 2.0 m (Ø) x 4.0 m

T up to 220°C; p up to 11 bar

3 – Autoclave (Italmatic)

Working size: 1.5m (Ø) x 5m

4 – Autoclave (Italmatic)

Working size: 2.5m (Ø) x 5m

n. 2 ovens:

1- CTM OVEN

Working size: 2m x 2 m x 1.5 m

T up to 300°C

2 – CTM OVEN

Working size: 3m x 2m x 2m

_06

Finishing

Specifications

n. 22 trimming stations

n. 3 automatic trimming stations

Spanesi coating system Compliant with the EN 13355 standard

Oven size 6.0 m x 4.0 m x 2.7m

Max drying temperature 90°C.

100 sqm. bonding area

Finishing involves refining the composite components: at this time we make sure that each product complies with the required standards both from a functional and aesthetic point of view.

_07

Coating

Specifications

Spanesi coating system, compliant with EN 13355

Oven size: 6.0m x 4.0m x 2.7m

Maximum drying temperature: 90°C

Ovens

CTM Oven 1

Dimensions: 2m x 2m x 1.5m

Maximum temperature: 300°C

CTM Oven 2

Dimensions: 3 m x 2 m x 2 m

_08

Quality control

Specifications

n.2 MetraSCAN 3D TM BLACK Elite

1,800,000 measures/second

0.025 mm accuracy

16 m³ scanning volume

Software: VX elements, Licenze VX Model and VX inspect

Dedicated area: 150 m²

_09

Thermal analysis

Specifications

Measuring instruments:

TG 209 F3 Tarsus

DSC 214 Polyma

Dedicated area: 150 m²